Profiled Solutions

Innovative solutions to difficult problems

Concrete Cutting

A recent customer needed to cut concrete slabs into smaller pieces as a part of the production of decorative brick. It was a difficult challenge due to the brittle nature of the material and the production speeds required to achieve the desired return on investment. Drawing on its experience, our team developed an innovative two-pass automated cutting system that was able to achieve maximum yield without sacrificing speed. This system gave the customer the ability to produce this product more profitably and deliver the product on time in the quantities desired.

Aluminum Cutting

Another customer had a challenge sizing aluminum components for garage doors. They had older machinery that was slow and did not have the accuracy needed for a modern manufacturing process. Most importantly the system was labor-intensive, and they were looking for a more automated solution. Like many customers, their desire for automation was not to eliminate jobs, it was because they could not hire enough people due to the labor shortage in manufacturing. One limiting factor was the space requirements were very tight. This system had to fit in an existing line, so not only did this system have to do more than the old machinery, it had to fit in the old space.

Our team got to work and once again, drawing on their decades of experience we’re able to develop an automated system that increased the speed and accuracy of the cutting of the aluminum components while maintaining the desired footprint.

Foam Cutting

Another customer needed to cut foam for insulated panels as a part of a new production line that was being established. Rather than replacing an existing machine or system, this was a “start with a white piece of paper project.” Once again, automation and speed were important, but the primary challenge came from the material to be cut. It would break into small pieces at high speeds unless fed into the cutting chamber in the right way.

Our team was able to overcome this based on our experience with similar materials. What would have been a unique problem to others was “old hat” for our team. As a result, we were able to design and build a system that met the customers’ needs, including their building schedule for their new line.

Profiled Solutions

Innovative solutions to difficult problems

Material Handling

A long-established customer in the door business needed to automate their production line. Specifically, they needed a system to feed doors into the production line, and then collect them at the other end in neat stacks which could then be moved to a different area of the plant. The challenge for them came from the fact they could not hire enough people to feed the machines fast enough, so automation was the only solution possible.

The challenge for our team was once again one of space. This new system needed to fit into an existing footprint. Our solution was not to go out or up but to go down. Our team designed from scratch an automated scissor lift system that was lowered into a pit on both sides of the machine system. This allowed the customer to feed their production line at the desired speed, in the space required, without the need for so many bodies.

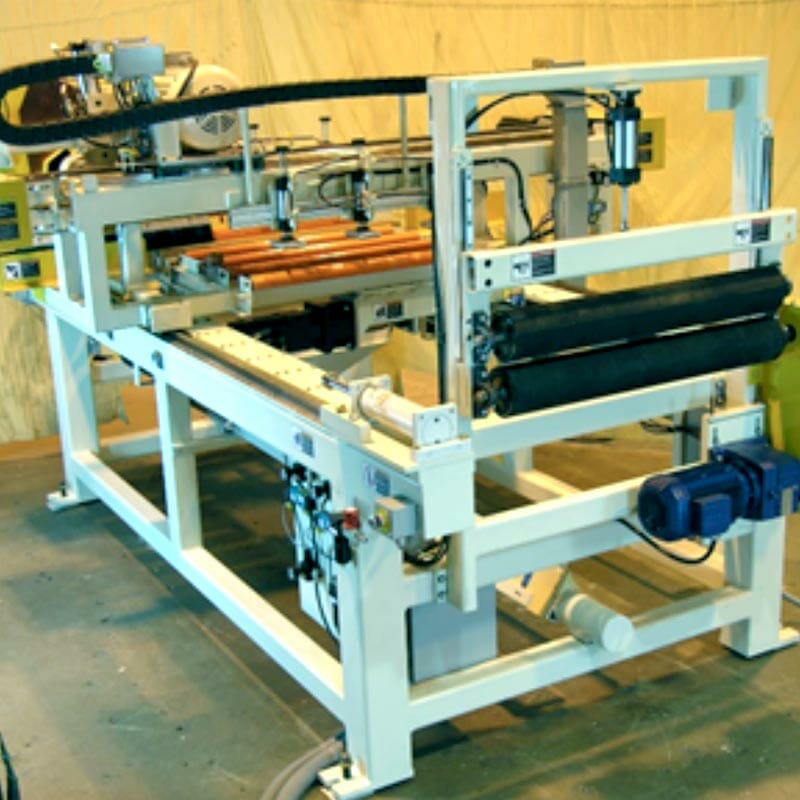

Material Handling & Cutting

A customer was developing a new production line for the purpose of cutting composite parts that have been affixed with a film veneer as a part of the production of wood flooring. While space wasn’t a major issue on this project, there were many other challenges. This automated system was being fed by other systems, and once the parts were processed, they would be fed into yet another system. This meant our automation was dependent on the speed of other systems on both the front and back end. Of course, the process had to be fast and involved lots of camera and sensor points to make sure the product was aligned properly when it entered the cutting chamber. And it had to be “two-pass” – which means it gets cut one way, gets turned on a transfer table, and then gets cut another way.

Fortunately, our design team has a tremendous amount of experience on two-pass processes, which resulted in a design that keeps the product properly aligned all the way through both passes. In addition, our depth of knowledge and experience about material handling ensured we were able to integrate this system into the overall larger factory operation. As a result, we were able to get the speed and accuracy required with minimal rejects.

Get in touch now

1905 Automation delivers advanced custom automation solutions that Increases Productivity, Quality, and Safety. Learn more about how we can make that kind of a difference in your bottom-line performance.

![Clayton Photo[2]](https://1905automation.b-cdn.net/wp-content/uploads/2020/09/Clayton-Photo2-1030x579.jpg)